Your Partner in Solutions that Optimize Critical Working Fluids

PT Fluida Teknologi Indonesia are a valuable partner in your goal to net zero, through energy transition solutions. Discover our comprehensive remedies to fluid contamination that offer an immediate path to a greener future.

We Enable Your Equipment to Do What It Was Designed to Do

Through innovation and a commitment to excellence, we help ensure that every wetted component and system operates optimally, supporting productivity and reliability every step of the way.

WELCOME TO PT Fluida Teknologi Indonesia

Pioneering Net Zero Solutions Today for a Cleaner Tomorrow

FluidTek’s mission is to provide cutting-edge solutions to foster a sustainable change in transition energy and propel us towards a net zero environment.

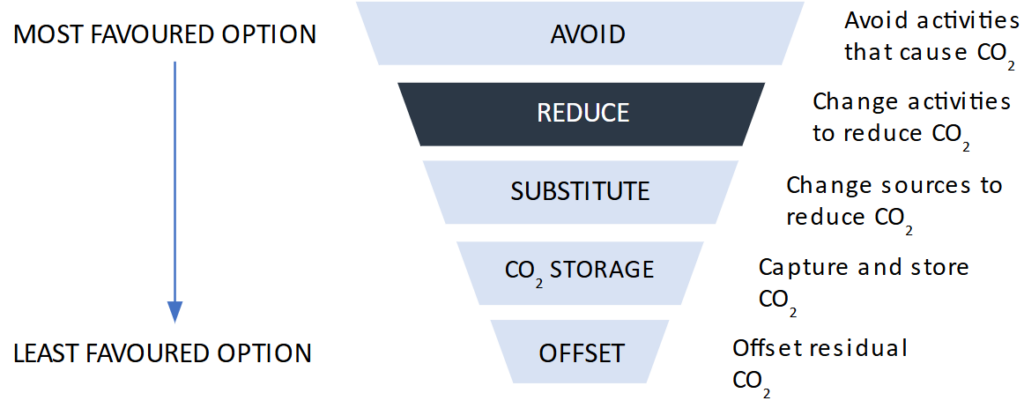

We focus on reducing CO2 in your operation by changing some of your existing activities. This is the 2nd most favourable option to minimizing CO2.

By changing the way Critical Working Fluids are stored and handled, contamination can be reduced creating significant operational benefits.

Fuel

- Improved engine performance

- Improved engine reliability

- Reduced exhaust emissions

- Reduced engine noise

- Reduced maintenance costs (wear and corrosion)

- Reduced fuel consumption

- Reduced waste (Increased fuel storage life)

Lubricants/Hydraulics/Cutting Oils:

- Reduced equipment/tooling wear

- Reduced energy consumption (Improved equipment efficiency)

- Reduced waste (Increased oil life)

Water

- Reduced corrosion

- Reduced deposits

- Reduced energy consumption (Improved heat transfer)

- Reduced treatment costs

Water

READ MORE

Water

We understand the critical challenges industries face in managing water resources. Fluida Teknologi Indonesia provides tailored water identification and quantification solutions for micro-organisms living in water systems. The latest ATP Gen II and qPCR technology allows the user to control contamination to ensure improved efficiency in HVAC systems and waste water: minimise spoiling of finished products in; Vehicle Production, Pulp & Paper, Food & Beverage and asset management in O&G pipelines, fuel storage tanks and more.

Water Focus |

Contaminants |

|

Clean Water Wastewater Industrial Water |

Microbes |

Fuel

READ MORE

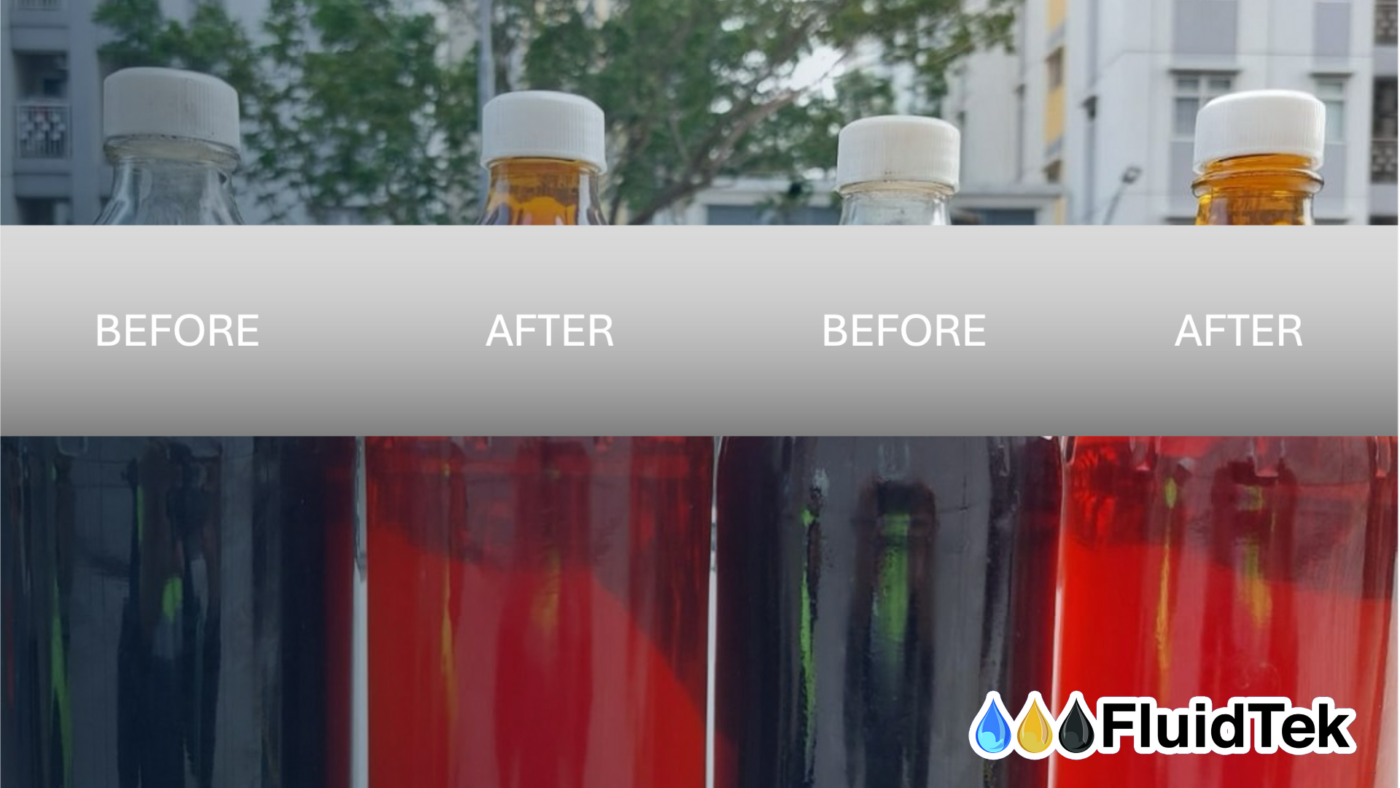

Fuel

We know the importance of effective fuel storage and handling in maintaining equipment performance. Fluida Teknologi Indonesia delivers comprehensive solutions for slow moving biodiesel fuel for standby power and fast moving biodiesel fuel in marine and land-based fleets. Improve power, reduce consumption, reduce engine wear, reduce emissions. Extending fuel life in long term storage.

Traditional aviation turbine fuel and the new Sustainable Aviation Fuels require frequent monitoring. The safety and performance of aircraft require frequent checks on microbial growth in fuel tanks to minimise corrosion and avoid fuel system blockages.

Fuel Focus |

Contaminants |

|

Biodiesel Aviation Fuel |

Water Particulate Microbes |

Oil (Lubricants)

READ MORE

Oil (Lubricants)

We recognize the complexities involved in lubricants and processing oil management. Fluida Teknologi Indonesia offers advanced oil management solutions addressing your needs for; improved storage and handling, efficient filtration and recycling to optimize performance and sustainability.

Oil (Lubricants) Focus |

Contaminants |

|

Lubricants Oil & Gas Pipelines Hydraulic Fluids Cutting Fluids |

Water Particulate Microbes |

More Than 25 Years’ Experience

We are the team behind PT Fluida Teknologi Indonesia, united by a shared commitment to excellence in fluid management and contamination control. With years of collective experience, we take pride in working together to deliver solutions that keep your operations running smoothly and efficiently.

As a team, we’re not just solving problems – we’re creating lasting partnerships with our customers.

Trusted By

Our Markets

Aviation

Aviation

The performance and reliability of aircraft heavily depend on the quality of aviation fuel (Avtur). Contaminated fuel with high levels of water or microbial growth can significantly impair engine efficiency and cause corrosion in the wing fuel tanks, leading to costly maintenance and unscheduled downtime.

Jet engines are particularly sensitive to such contamination, as they require clean, high-performance fuel to ensure smooth operation and extended lifespan. Additionally, emissions regulations in aviation demand solutions that not only protect engines but also reduce environmental impact.

FluidTek’s tailored solutions safeguard aviation fuel by monitoring water content and eliminating microbial contamination.

Baseload Diesel Power

Baseload Diesel Power

Whole communities rely on continuous uninterrupted power. Often locations using diesel power are remote and have only one main fuel storage tank. If the fuel is highly contaminated it will affect all gensets, it will also reduce the duration between maintenance and repair works on the storage tank. Higher fuel consumption, poor engine performance and increased lube oil changes add costs and decrease reliability.

FluidTek’s solutions reduce costs and increase reliability to keep gensets running with less fuel, less exhaust emissions and less maintenance.

Buildings - Standby Power

Buildings - Standby Power

Commercial Buildings, Data Centre and Critical Facilities.

Food And Beverage

Food And Beverage

This industry is in a constant battle against microorganisms. These single cell microbes affect human health, product quality and corrosion in the processing equipment.

FluidTek provides rapid, accurate on site testing providing the operator the information required to take control of the process. Reducing costs from failed QA testing and proactive maintenance of the equipment.

Industrial Processing

Industrial Processing

Many industrial processes, once started, cannot be stopped without huge losses. Refining and smelting are two of these industries.

FluidTek’s products and services offer many ways to reduce the total cost of production and minimise waste in process oil, lubricant and water systems, with accurate and rapid onsite testing and monitoring. Our solutions include better sampling systems to ensure the test represents what is in the system.

Industrial Water

Industrial Water

From pulp and paper production to EDP coatings in automotive manufacturing and others, these industrial processes require large volumes of water. In these applications, the quality of the water has a direct influence on the quality of the finished goods. Microbial growth is a major contaminant that must be controlled.

FluidTek’s solutions can assist in optimizing water usage, enhancing operational efficiency, and support sustainable practices. Rapid and accurate on site microbial testing reduces variability in the process, reduces biocide dosing and reduces costs of production.

Marine

Marine

Marine operations require reliable power sources that can withstand harsh sea conditions. Our solutions are engineered for durability and efficiency, ensuring that marine vessels and offshore platforms maintain continuous power supply. Whether for propulsion or auxiliary power, our systems offer a sustainable alternative that reduces environmental impact while enhancing operational reliability

Oil & Gas

Oil & Gas

Microbial influenced corrosion (MIC) is a significant maintenance and operation cost in the oil and gas sector, especially in product transfer pipelines. Microbial growth is also common in offshore cooling systems.

FluidTek’s solutions reduce the time to identify these issues with highly accurate and rapid field testing. Allowing operators to control their costs and increase uptime.

On & Off Highway Fleets

On & Off Highway Fleets

FluidTek offers comprehensive solutions to elevate the performance of both on-road and off-road vehicle fleets. Our fuel filtration and conditioning technologies ensure vehicles operate at peak efficiency, while extending engine life. We understand the critical nature of fleet reliability and strive to reduce the total cost of transporting goods.

Port Facilities

Port Facilities

Ports are vital hubs of global and local trade. STS Cranes, RTGs, Reach Stackers, Forklifts and other port equipment must be reliable and efficient to avoid demurrage costs.

Poorly stored and distributed fuel at the port will impact all diesel powered equipment. Low performance, increased exhaust emissions and premature component failure, eg injectors can be costly for the operation.

FluidTek understand the unique challenges for port facilities and provide tailored solutions to reduce ship loading and unloading facilities total operating costs.

Wastewater

Wastewater

This market is unique in that what may be contamination in other markets is vital to the effective management of waste water.

Like cholesterol, there are good microbes that need to be protected, while the bad microbes need to be removed.

FluidTek offer a service that can rapidly and accurately identify what is happening in your waste water to allow you to take control.

This solution provides a more efficient waste process, and confidence that waste water meets the appropriate regulations, before it is returned to the environment.

Our Partners